What is SWOT?

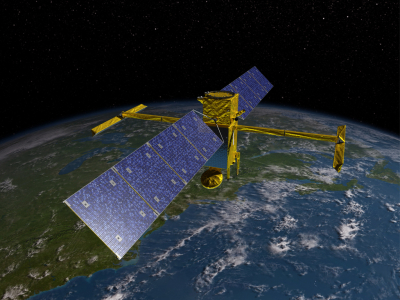

The satellite has been designed to conduct a landmark survey of the world's oceans, lakes, and rivers from space for the first time.

NASA, the U.S. space agency, recently launched a satellite called SWOT. What is its objective and how will it help us? Let's find out.

Its mission

SWOT, short for the Surface Water and Ocean Topography satellite, was recently launched from California to make a comprehensive survey of the world's oceans, rivers, and lakes from space for the very first time. Dubbed a "revolution in hydrology", SWOT, an SUV-sized satellite flying at a height of 890 km, will offer an unprecedented, clear view of the water bodies, while tracking the rise in sea levels, as well as rivers, lakes, and reservoirs. The satellite is expected to offer key insights into how these bodies of water influence climate change and factors such as how much more heat and carbon dioxide oceans can absorb. Oceans are estimated to have absorbed more than 90% of the excess heat trapped in Earth's atmosphere caused by human-induced greenhouse gas emissions. With climate change accelerating, some regions are experiencing extreme droughts. while others extreme floods, along with changing precipitation patterns. According to researchers, the observations of SWOT will improve our understanding of how water moves around Earth, its circular currents in oceans, etc. This will help predict floods in areas where there is too much water, and manage water in places that are prone to drought.

How will it work?

The global water survey satellite will measure the height of water in freshwater bodies and the ocean on more than 90% of Earth's surface - which it will track at least once every 21 days. Researchers will be able to get data on millions of lakes, rather than the few thousands currently visible from space. The technology employed by SWOT is called KaRin, a Ka-band radar interferometer. The radar sends down a signal which is reflected back by the water surface. This echo is received by two antennas, resulting in two sets of data providing high accuracy for water detection and resolution. The data, compiled from the radar sweeps of the planet, will be used to bolster weather and climate forecasts and aid in managing scarce freshwater supplies in drought-stricken areas.

Who developed it?

The satellite is a billion-dollar project developed jointly by NASA and France's space agency CNES, with contributions from the Canadian space agency and the U.K. space agency. It was carried onboard a spacex Falcon-9 rocket from the Vandenberg U.S. Space Force Base. SWOT will start collecting scientific data in about six months time after undergoing checks and calibrations. The satellite's components were built primarily by NASA's Jet Propulsion Laboratory near Los Angeles and CNES.

According to SWOT'S project head at CNES, Thierry Lafon, the mission is meant to last for three-and-a-half years, but could be extended. The U.S. and French space agencies have worked together in the field for over three decades. An earlier satellite developed by the two agencies, TOPEX/Poseidon, improved understanding of ocean circulation and its effect on global climate. It also aided the forecast of the 1997-1998 El Nino weather phenomenon.

Picture Credit : Google